What are the common processes for graphite mold manufacturing

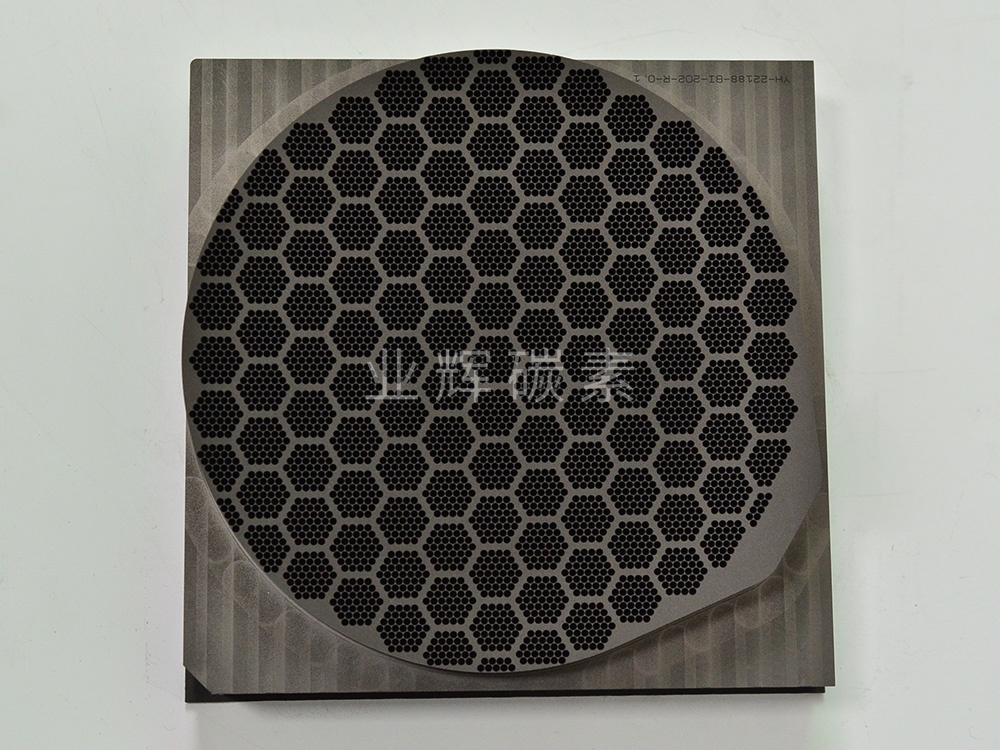

時間:2022-09-29瀏覽次數:2806Graphite mouldThis kind of product, which is not in this field, will not be known by many people. But it is very important for the development of industrialization, such as electromechanical, household appliances and light industry. In the process of making graphite molds, there are also many manufacturing processes. Next, let's look at the common processes of graphite mold manufacturing.

The characteristics of graphite stamping die are high precision, accurate specification, and the clearance between die seat and cavity of some stamping dies tends to zero. The pressing speed of the mold is faster, and the pressing speed of the mold is dozens or hundreds of times per minute. The service life of abrasives is long, and the service life of some ferrite core cold stamping dies is about one million times.

The graphite die stamping die is a grinding tool for forming and separating thick plate stamping die. The forming milling cutter has a concave die, and the split milling cutter has a tooth surface. The common stamping die has only one fixture to complete a manufacturing process. Abrasives are widely used, simple in structure, easy to manufacture, but low in productivity. Multiple stamping die processes such as blanking, drawing, punching and trimming can be distributed in one polishing tool to improve production efficiency. Therefore, multiple stamping dies can be used in one fixture to make blanks. This abrasive is called a composite die. In addition, blanking, bending, stretching, punching, trimming and other processes are distributed in different grinding fixture. In the whole process of the stamping die, the blank is formed by a continuous stamping die according to a number of fixtures in turn, and the fixture is produced. This abrasive is called a stamping die or a continuous die.

Forging is a kind of abrasive tool for forging hot metal materials. In the process of die forging, the steel billet usually needs to be deformed for many times before it can be made into cast steel. Therefore, multiple dies need to be cut in one control module. The metal is continuously fed into each female mold, where it flows plastically and subsequently fills the female mold to produce steel castings. In die forging, the blank cannot have the same volume as the final forging die. In order to reduce waste, we often use slightly larger blanks. Therefore, burr grooves are arranged around the upper die of the forging upper die and the upper die of the final forging die to store unnecessary metal materials and remove burrs after forming.

The technical characteristics of forging die are: there are a variety of complex concave shapes, the working standard is extreme, the red steel at about 1000 ℃ is deformed in the abrasive tool die, and the fluidity is eroded. The grinding tool should be able to withstand the high-speed impact or heavy load of the forging hammer. Rapid cooling, rapid heating and alternating high and low temperatures are common throughout the application process. Therefore, metal materials need to have high compressive strength, ductility and wear resistance. High temperature compressive strength, strength during hot forging, toughening and tempering are also required.

The die-casting die is installed on the aluminum die-casting machine. Under high pressure, shape memory alloy can be introduced into the concave die and the pressure can be maintained until the metal materials condense to form abrasives, which is applicable to aluminum, zinc, copper and iron castings. The structure of the die casting mold is similar to that of the plastic injection mold. The movable mold and the fixed mold form a female mold, and the core is used as a pouring cavity. The metal is cooled and condensed in the female mold, removed from the core and separated from the graphite mold.

Generally speaking, castings are thin and hollow, with many abutments and reinforcements, complex appearance and structure, accurate specifications and smooth surface. Metal materials are formed at a higher melting temperature, so die-casting dies need to be made of heat-resistant materials.

The extrusion die is a grinding tool for extruding metal materials. The positive extrusion die has a fixed cavity, an extrusion cylinder for placing blanks and a punch for pressing blanks. The extrusion barrel of the reverse extrusion die is a cavity, and the punch is a die seat. The metal materials can only be extruded from the cavity under high air pressure, so the extrusion cylinder and the cavity formed by back extrusion need to have high compressive strength, and the structure is composed of two layers of prestressed steel, and a bar is selected. The length of punch and die seat shall be short to prevent instability and bending under high compression stress.

Those who have used graphite moulds know that the moulds used for manufacturing and processing metal materials are classified according to the selected manufacturing process. Common moulds include cold pressing moulds, bending moulds, drawing moulds, flanging moulds, shrinkage moulds, waveform moulds, bulging moulds, plastic and decorative moulds, and forging moulds, upsetting moulds, etc. Its extrusion die and die casting die. Moulds used for non-metallic materials and powder metallurgy production and processing are named and classified according to their production and processing purposes, such as molds, vulcanized rubber molds and powder metallurgy molds.