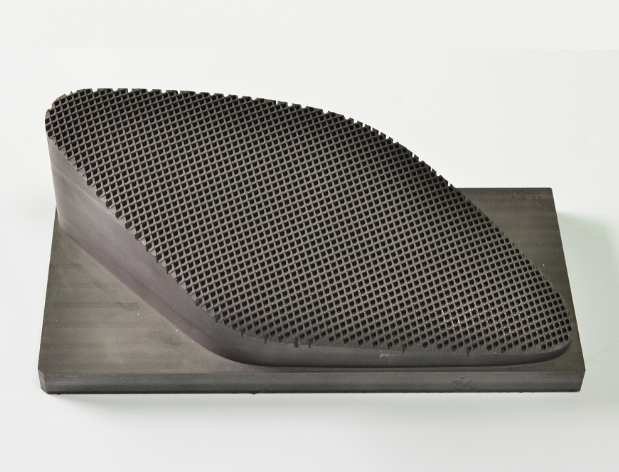

EDM graphite electrode

時間:2022-07-28瀏覽次數:5180

EDM graphite, also known as graphite for EDM, is a new type of material, which is now more and more widely used in the precision mold processing industry. At present, more than 90% of the mold processing electrode materials in the mold processing plants in developed European countries are graphite. Copper, once dominant electrode material, has almost lost its advantages over graphite electrode. Why is this? Graphite has great advantages as a discharge material for EDM. Since the spark oil also contains C atoms, the C atoms in the spark oil are decomposed at high temperature during EDM, so that a protective film is formed on the surface of the EDM graphite electrode to compensate the loss of the graphite electrode. Therefore, the loss of the graphite electrode is very small, so the service life is long.

Product features of EDM graphite:

China's manufacturing industry is developing in the high-end direction. The country is vigorously promoting intelligent manufacturing and building a manufacturing power. Therefore, in the field of precision mold manufacturing, the requirements for the discharge materials used for processing are becoming higher and higher. Therefore, EDM graphite, that is, EDM graphite, is playing a higher and higher role in the processing of these precision molds. Therefore, the industry has paid high attention to the screening of EDM materials

EDM EDM graphite electrode advantages:

1. Faster processing speed. In general, the machining speed of graphite is 2-5 times faster than that of copper, and the discharge speed is 3-5 times faster than that of copper.

2. The material is less easy to deform, and has obvious advantages in the processing of thin rib materials. The softening point of copper is about 1000 degrees, which is easily deformed by heating. The sublimation temperature of graphite is 3650 degrees, and the thermal expansion coefficient is only 1 / 30 of that of copper.

3. Lighter weight. The density of graphite is only 1 / 5 of that of copper. When large electrodes are used for electrical discharge machining, it can effectively reduce the burden of machine tools (EDM) and is more suitable for application in large molds.

4. Less discharge consumption. Since the spark oil also contains C atoms, during EDM, the high temperature causes the C atoms in the spark oil to be decomposed, and then forms a protective film on the surface of the graphite electrode to compensate for the loss of the graphite electrode.